SAND MOLD CASTING

Molding sand molds

We are fully equipped to handle the three processes of self-hardening furan, CO, and cold-box.

Because production costs are lower than metal mold casting, this method is suitable for small-lot production, prototypes for making design modifications, and large-sized casting.

The cold-box process uses compressed air to fill a mold with sand, so cores that cannot be filled with sand by hand and complex shapes can be molded without any non-uniformity. In addition, artificial sand is used so it is suited to products with high demands for cast surface roughness and products that do not require polishing.

Gravity casting

The oldest casting method, molten aluminum is poured into a mold made with casting sand, the sand mold is broken after cooling solidification, and the product is then extracted.

Sand mold casting makes molding easy and enables the production of a wide range of items ranging from objects with small dimensions to large-scale products.

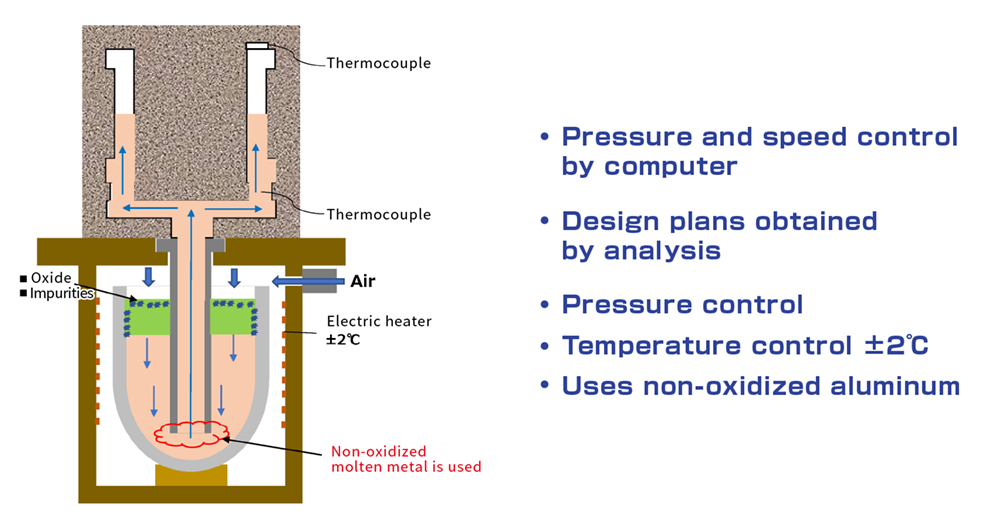

Low-pressing casting

Low pressure is applied to the surface of the molten metal in the furnace and molten aluminum is forced through a stoke (hot-water supply pipe) soaked in molten metal, and then injected into the mold.

This method keeps on applying pressure until solidification from the top of the mold to the gate is complete.

A feature of this method is that it enables high-quality casting as it ensures even material without any non-uniformity.

In addition, this process is extremely close to the ideal “gently and quickly” pouring conditions for casting.

Miura controls temperature and pressure conditions by computer, so we are extremely adept at reproducibility.

The maximum casting weight is 550 kg.